Unlock New Levels of Productivity with Our High-Precision Rubber Segmented Collet

Envision Introduces High-Precision Custom Rubber Segmented Collet, Redefining Clamping Accuracy & Efficiency

[XIAN, 11, 6th, 2025 ] – [Envision Industry], a leading provider of precision workholding solutions, today announced that its core product—high-precision Custom Rubber Segmented Collet,—is successfully helping manufacturers overcome critical workpiece clamping challenges. This product is becoming a secret weapon for enhancing production line competitiveness,

thanks to its exceptional repeatability of up to ±0.05 mm, unmatched changeover speed, and fully personalized custom design.

In the landscape of modern manufacturing, where efficiency and precision are paramount, traditional rigid arbors or jaws often fall short.

They can struggle to absorb vibrations, potentially distorting thin-walled parts, and their slow adjustment processes hamper Overall Equipment Effectiveness (OEE).

The rubber expansion arbor from Envision was engineered specifically to address these pain points. Innovative by Design, Exceptional in Performance.

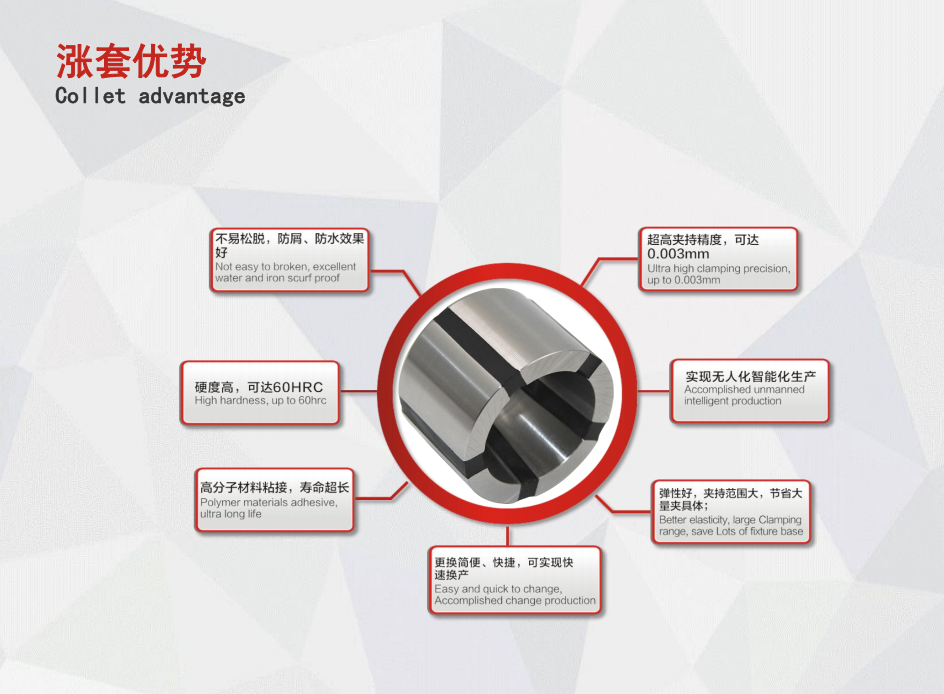

The product's superiority stems from its innovative design and precision manufacturing:

Unwavering Bond Strength for Maximum Durability: A patent-pending bonding process creates an incredibly strong connection between the rubber elastic body and the metal mandrel.

This effectively prevents loosening or separation under high-speed rotation and heavy cutting loads, ensuring a service life that far exceeds industry standards.

Micron-Level Precision You Can Trust: Through strict material control and precision machining, these arbors achieve consistent repeatability within ±0.05 mm.

This makes them ideal for high-standard machining of precision components like gears and bearing rings, virtually eliminating scrap caused by positioning deviations.

Tailor-Made for a Perfect Fit: We understand that a one-size-fits-all solution is rarely optimal. That's why we offer comprehensive customization—

from the arbor's diameter and length to the rubber's hardness and profile—all optimized for your specific workpiece, machine tool, and process to ensure seamless integration into your existing production line.

Driving Tangible Business Value

For the end-user, these technical advantages translate directly into significant economic benefits:

Drastically Reduce Downtime with Lightning-Fast Changeovers: The simple design allows operators to change the arbor in seconds.

Compared to traditional fixtures, this can reduce machine downtime by an average of up to 70%, leading to superior asset utilization.

Boost Productivity and Yield Rates: Rapid clamping combined with high precision accelerates production cycles and nearly eliminates part scrapping due to fixturing issues,

potentially increasing overall production efficiency by over 25%.

Lower Total Cost of Ownership: Reduced downtime, higher yield rates, and extended tool life collectively contribute to a lower cost-per-part and a faster return on investment.

Envision Industry is a professional foreign trade company, we representative of the factory with high-tech enterprise specializing in the design, manufacturing,

and sales of high-end precision fixtures, jigs, and automated workholding.

Driven by technological innovation and a customer-centric approach, the company is dedicated to providing global manufacturing clients with core solutions that enhance production efficiency and product quality.

Contact us by email rose@envisionindustry directly, we are ready to help.